Gravitational Energy Storage Systems

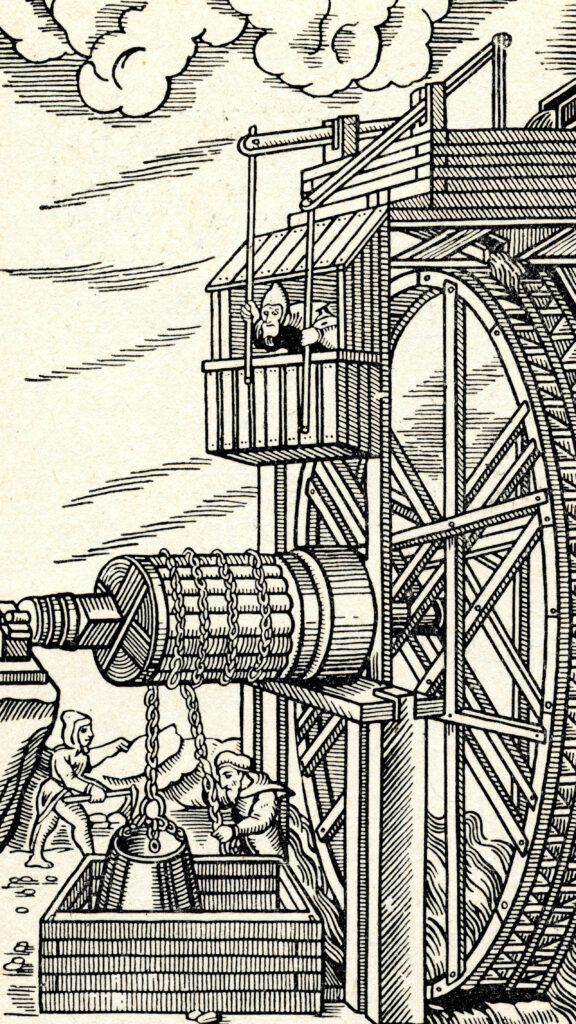

The idea of using gravity as a means of storing energy is not a new concept; and it has been explored in various forms throughout history. The concept of using gravity to generate power dates to ancient times. The Greeks, for example, used water wheels to generate power (Figure 1), and the Romans used aqueducts to transport water to their cities (Figure 2). The first modern gravitational energy storage system was developed in the late 19th century. This system involves pumping water uphill during periods of low demand and allowing it to flow downhill through turbines to generate electricity during periods of high demand.

In recent years, there has been renewed interest in using gravity as a means of storing energy, and several new systems have been developed. These include systems that use weights suspended in mine shafts to store energy as well as tower-based systems that use custom-made concrete blocks or heavy masses to store energy.

One example of a gravitational energy storage system is the pumped storage hydropower (PSH). In this system, water is pumped from a lower reservoir to a higher reservoir when there is excess electricity on the grid. When there is a shortage of electricity, the water is allowed to flow back down to the lower reservoir through a turbine, generating electricity in the process.

The field of gravitational energy storage is still relatively new. Currently, only a handful of companies and organizations are working on developing and implementing these systems. Some of the major projects include:

- Energy Vault is a Swiss company that has developed a tower-based gravitational energy storage system. The system uses custom-made concrete blocks that are lifted and stacked by cranes to store energy. When the energy is needed, the blocks are lowered, generating electricity in the process.

- Gravitricity is a UK-based company that is developing a system that uses weights suspended in mine shafts to store energy. When the energy is needed, the weights are released, driving a generator and producing electricity.

- ARES (Advanced Rail Energy Storage) is a California-based company that has developed a system that uses electric locomotives to transport weighted railcars up a hill. When energy is needed, the railcars are allowed to roll back down the hill, generating electricity in the process.

- Hydrostor is a Canadian company that has developed a system that uses compressed air to store energy underwater. When the energy is needed, the compressed air is released, driving a generator and producing electricity.

Benefits, Limitations, and Efficiencies

Gravitational energy storage systems offer several potential advantages over other types of energy storage. For instance, gravitational energy storage systems can store energy for long periods of time, making them ideal for storing excess energy from intermittent renewable sources like wind and solar power. They can also be scaled up or down to meet the needs of different energy storage applications. For example, smaller systems can be used to provide backup power for homes or businesses, while larger systems can be used to support entire grids. For the most part, gravitational energy storage systems are generally simple and low-maintenance compared to other types of energy storage systems, such as lithium-ion batteries, and these systems are typically more environmentally friendly than traditional fossil fuel power plants, as they do not produce greenhouse gas emissions or other harmful pollutants.

There are, however, some limitations and drawbacks to these systems. For instance, many gravitational energy storage systems, such as PSH systems, require specific geographical features, such as hills or mountains, to operate effectively. This can limit their potential deployment in some areas. Also, most gravitational energy storage systems have a high upfront cost, making them expensive to build, particularly when compared to other types of energy storage systems like lithium-ion batteries. Also, gravitational energy storage systems can experience efficiency losses during the energy storage and retrieval process, which can result in lower overall energy efficiency. Lastly, there are the safety concerns. Gravitational energy storage systems can pose safety risks if not designed and operated properly, particularly in cases where large masses are suspended or moved in the system.

The efficiency of gravitational energy storage systems can vary depending on technology, conditions, and generally have lower round-trip efficiency compared to lithium-ion batteries. A PSH system, the most widely used gravitational system, typically has round-trip efficiencies of 70-85 percent, with 15-30 percent energy loss due to friction and other inefficiencies. Lithium-ion batteries, in contrast, have round-trip efficiencies of 85-95 percent, with lower losses. However, lithium-ion batteries have limitations in energy capacity and discharge rates, limiting suitability for some applications. On the other hand, gravitational systems can be improved through design and materials. Their long-duration storage and low maintenance advantages may make them viable in certain situations.

Featured Products

This week’s New Tech Tuesday highlights industry-leading products from Phoenix Contact and MEANWELL. These suppliers prioritize superior design, quality, and reliability, supporting sustainable applications with improved efficiency and cost reduction.

Experience reliable connections and high-quality performance with Phoenix Contact terminal blocks. The new XT and XTV terminal blocks with Push-X technology enable tool-free connections of rigid and flexible conductors, with or without ferrules. The pretensioned contact chamber allows fast and effortless wiring, reducing time and effort. Tested beyond standard requirements, Push-X technology is suitable for industries with demanding needs for vibration resistance, gas tightness, and robustness. These terminal blocks are fully compatible with Phoenix Contact’s CLIPLINE system.

In addition to the advanced XT and XTV terminal blocks, Phoenix Contact offers the PROJECT complete software, an innovative solution for streamlined terminal strip planning and professional marking. This software supports a wide range of marking materials for terminal blocks, conductors, cables, devices, and systems. It integrates smoothly with popular CAE programs, facilitating efficient data import and automatic terminal strip design. PROJECT complete is compatible with Phoenix Contact printing systems as well as standard printers, providing comprehensive control over terminal strip design and printing tasks. Enhance your workflow with the PROJECT complete software from Phoenix Contact.

MEAN WELL, the global leader in standard power supply, has developed the energy-efficient ERG-5000 series energy recycling grid type power inverter. These power inverters are ideal for front-end manufacturing, battery production, and test equipment applications. They are also suitable for end products, charging piles, energy storage systems (ESS), and various energy applications.

The 5kW ERG-5000 series provides a complete solution for energy manufacturing, recycling, and integration into the power grid. With over 80 percent energy recovery and savings, it features full digital controls and can be used with the MEAN WELL’s CMU2A intelligent controller for remote or direct monitoring.

The programmable control functions allow independent setup of input and output voltage modes as constant current or constant voltage via CANbus protocol or the CMU2A controller. Additionally, the ERG-5000 series includes built-in monitoring signals for key alarms like over temperature, grid fault, and overvoltage.