Flat Pasta Developed That Morphs Into Shape When Cooked

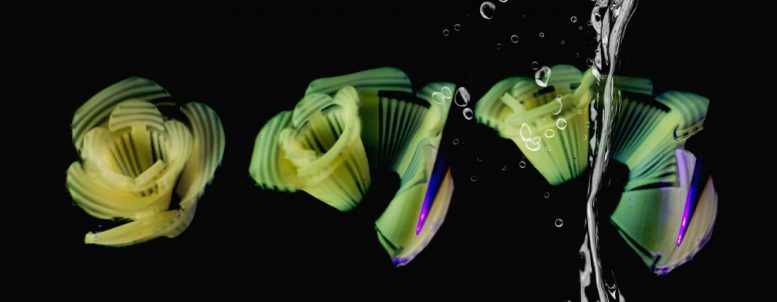

CMU Lab leads development of pasta that morphs into shape when cooked. Credit: Carnegie Mellon University

Flat-packed noodles create more sustainable packaging, transportation and storage.

People love pasta for its shapes — from tubes of penne and rigatoni to spirals of fusilli and rotini.

But what makes farfalle different from conchiglie also makes the staple a bear to package, requiring large bags and boxes to accommodate the iconic shapes of pastas around the world.

A research team led by the Morphing Matter Lab at Carnegie Mellon University is developing flat pasta that forms into familiar shapes when cooked. The team impresses tiny grooves into flat pasta dough — made of only semolina flour and water — in patterns that cause it to morph into tubes, spirals, twists, and waves when cooked.

The morphed pasta looks, feels and, most importantly, tastes like traditional pasta, while opening new possibilities for food design and allowing for flat-packed pasta that would cut back on packaging, save space in storage and transportation, and possibly reduce the time and energy needed for cooking.

“We were inspired by flat-packed furniture and how it saved space, made storage easier, and reduced the carbon footprint associated with transportation,” said Lining Yao, director of the Morphing Matter Lab in the Human-Computer Interaction Institute at CMU’s School of Computer Science. “We decided to look at how the morphing matter technology we were developing in the lab could create flat-packed pastas that offered similar sustainability outcomes.”

[embedded content]

The team published their understanding of the morphing mechanism and design principles in the paper “Morphing Pasta and Beyond,” which is the cover story of the May 2021 issue of Science Advances. Authors include 17 researchers from CMU, Syracuse University and Zhejiang University, specializing in fields including material science, mechanical engineering, computational fabrication and design.

The grooves stamped into the flat pasta sheets increase the time it takes water to cook that area of the pasta. By carefully planning where and how to place the grooves, the researchers can control what shape of pasta forms when it is cooked.

“The groove side expands less than the smooth side, leading the pasta to morph into shape,” said Teng Zhang, an assistant professor at Syracuse University who led the modeling analysis in this project.

Grooves can be used to control the morphed shape of any swellable material. The team has demonstrated that it can morph silicon sheets using the same groove technique.

“This could potentially be used in soft robotics and biomedical devices,” said Wen Wang, a former researcher affiliated with the Morphing Matter Lab.

The plastic material used in food packaging contributes greatly to landfills worldwide, and packaging litters the world’s oceans. Creating effective food packaging is crucial to reducing waste and shaping a sustainable future. Flat-packed pasta would cut back on the packaging required while saving space in shipping and storage.

The team also envisioned that their flat-packed pasta may lower the carbon footprint of cooking. In Italy, about 1% of greenhouse gas emissions come from cooking pasta. Flat pasta may cook faster than tubular pasta, which could possibly reduce emissions during the cooking process.

Ye Tao, a former visiting postdoctoral researcher at the Morphing Matter Lab and the study’s lead author, tested the flat-packed pasta in the wild by packing it for a hiking trip. The pasta took up less room in her bag, did not break while hiking, and cooked successfully on a portable camp stove.

“The morphed pasta mimicked the mouthfeel, taste, and appearance of traditional pasta,” she said.

Traditional pasta already morphs when cooked, expanding and softening when boiled. The team harnessed these natural properties to create its flat-packed product.

The morphing pasta builds on years of research by Yao and the Morphing Matter Lab on morphing mechanisms and applications with different materials ranging from plastic and rubber to fabric and food.

Reference: “Morphing pasta and beyond” by Ye Tao, Yi-Chin Lee, Haolin Liu, Xiaoxiao Zhang, Jianxun Cui, Catherine Mondoa, Mahnoush Babaei, Jasio Santillan, Guanyun Wang, Danli Luo, Di Liu, Humphrey Yang, Youngwook Do, Lingyun Sun, Wen Wang, Teng Zhang and Lining Yao, 5 May 2021, Science Advances.

DOI: 10.1126/sciadv.abf4098

The research was funded by the U.S. National Science Foundation, the CMU Manufacturing Futures Initiative and the National Natural Science Foundation of China.