DIY: How to Make Your Own Hatchet

Have you ever thought, “Gee, I think I’d like to make myself a hatchet today?”

Yes?

Then today’s your lucky day! With some scrap steel, a hacksaw, a file, a drill, a bonfire, a bucket of water, and an oven, you can make this simple, hardy, “democratic” axe. Don’t believe it? Read on!

The following excerpt is from A Handmade Life: In Search of Simplicity by William Coperthwaite. It has been adapted for the web.

When love and skill work together, expect a masterpiece.

—John Ruskin

It is hard to find a good broad hatchet—a small, broad axe with a wide cutting edge beveled on only one side, like a chisel; this special bevel makes it easier to hew to a line.

After forty years of hunting in antiques shops and flea markets, I have found only two broad hatchets that passed muster. To friends who sought one of their own, the outlook was discouraging. They could get one made—if they happened to know a good blacksmith, if they had a good design, and if they could afford the price.

Or you could forge one yourself, but by the time you had learned to make a fine one, you would have become a blacksmith yourself. This is an elite tool.

In Japan, in the Tosa region of the island of Shikoku, I was surprised by the number of blacksmiths. Each village had its smith, and all could make excellent edge tools. It was delightful to see the grace and skill of those smiths. I became friends with one who made a broad hatchet to my specifications. Twenty years went by, and in the interim I had studied many axes and was blending what I had learned into my ideal of a broad hatchet.

In Japan, in the Tosa region of the island of Shikoku, I was surprised by the number of blacksmiths. Each village had its smith, and all could make excellent edge tools. It was delightful to see the grace and skill of those smiths. I became friends with one who made a broad hatchet to my specifications. Twenty years went by, and in the interim I had studied many axes and was blending what I had learned into my ideal of a broad hatchet.

A few years ago I carved a pine model and sent it off to my blacksmith friend in Shikoku. Yes, he would make it for me. Two years passed and it did not appear. I assumed the project was forgotten.

While visiting Italy, I came upon an elderly smith who had made axes years ago. I carved another pattern, and he forged the axe. Now, these are far from democratic tools. To get one you first have to design it and then know a smith in Japan or Italy or wherever who can—and is willing to—make an axe from your design.

It was doubtful that the axe from Japan would materialize, and the Italian smith was very old and sick and would probably not make another. A good broad hatchet for students and friends who wanted one was as elusive as ever. And though this axe adventure was exciting, and I had acquired some fine ones, we badly needed to have some inexpensive ones available.

While studying in Switzerland the breakthrough came. The tiny fellow who lives upstairs above my right ear (and works mostly at night) shouted “Eureka!” He presented me with a full-blown design for a democratic axe.

I could hardly wait to get back to my bench. For steel there was an ancient plow point of about the right thickness lying behind the barn. Into the bonfire it went and when glowing red, we heaped ashes over it and let it remain until morning, cooling slowly and releasing its hardness. Next day I reheated and hammered it flat using a handy ledge for an anvil. When it cooled, I drew the pattern on it. Three hours of work at the vise was needed to cut it to shape with a hacksaw and another hour to dress it with files.

For us amateurs in axe making, there are two major difficulties.

One of these is forging the eye of the axe—the hole into which the handle is inserted in a conventional axe. This democratic design eliminates the eye. The other difficulty is tempering, or bringing the steel to the correct hardness. Smiths have long been respected for their skill at this magical process of tempering steel, which requires good judgment and much experience to be able to do dependably.

One of these is forging the eye of the axe—the hole into which the handle is inserted in a conventional axe. This democratic design eliminates the eye. The other difficulty is tempering, or bringing the steel to the correct hardness. Smiths have long been respected for their skill at this magical process of tempering steel, which requires good judgment and much experience to be able to do dependably.

After a good deal of pondering, experimenting, and reading all that I could find on tempering, some of the mystery began to fade. Before tempering, the steel must be hardened by being brought to red heat and then plunged in water. Then it seemed that tempering was merely a matter of temperature control. So we put the axe in an oven set at 475°F for half an hour and let it cool slowly. This worked!

Now, you smiths may object, reminding us that a tool like an axe that gets a blow needs to be soft in the eye to resist breaking. To this charge I plead nolo contendere. However, a broad hatchet is made with a short handle for use on a block, and such hatchets do not undergo the same severity of blows.

For the first time, we now have a democratic axe—an axe that most anyone who wants one can have. (You say you never knew you needed an axe, and I say, very well. Even so, here we have another example of one more democratic tool, which will make design of the next one a little easier, whatever its purpose.)

This experience with the broad hatchet is important for me on several levels. First it has been a exciting adventure all along the way, from learning to appreciate the variations in different forms of such a basic tool, to designing my own which others made, to ultimately making my own. Another level of the adventure is to be able to help others make their own hand axes and in the process gain the confidence that comes from making a tool. This process demonstrates how we can have adventure in a variety of ways: designing, working with the hands, and working with the mind as we carry the concept of democratic things further.

Another value this experience has had for me is the breaking of mental and social barriers, which we need to be able to do if we are to solve our problems and create a decent society that works for all people.

At times the outlook appears very dark. It would seem our problems are insurmountable. As with this little hand axe, I was quite sure that I would never make my own. And yet, without consciously focusing on the problem directly, unconscious forces were at work and discovered a solution. This gives me hope that if we can continue searching and caring and supporting one another—we may be able to find the solution to even our worst problems.

P.S. The broad hatchet from Shikoku finally arrived. It is a veritable gem. Actually, two came—a left- and a righthanded one—polished to a mirror finish and gently wrapped in small white towels.

To Make an Axe:

-

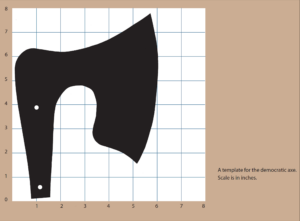

Trace the pattern on the next page on annealed (temperable) steel, 5/16-thick.

-

Cut out the axe head with a hacksaw.

-

Smooth all edges with a file, and file the bevel to make the cutting edge. (For a right-hander, the bevel should be on the right, for a lefty on the left.)

-

Drill two rivet holes.

-

The face should be slightly hollowed, like a shallow gouge. To do this, carve a hollow (6 inches long and 1/4 inch deep) in a chopping block. Heat the axe head until it is glowing red, then hammer it into the hollow with the bevel side up.

-

To harden the steel, heat it to glowing red and plunge it immediately into cold water.

-

To temper the steel, put the axe head in an oven at 475°F for about twenty minutes and allow to cool slowly.

-

Carve a handle of hardwood in the form shown in the photograph and rivet it to the axe head. You can customize the handle’s curve and weight to your own preferences.